Why mesa parts?

What we do, few others can. That’s why we develop our machinery and measurement technology specifically for our requirements – together with experienced specialists. In addition, we have the knowledge and experience to optimize turned parts and process chains in close collaboration with you.

- In-house special-purpose machine construction

- Series readiness from the very beginning

- Reliable quality

- Global production security

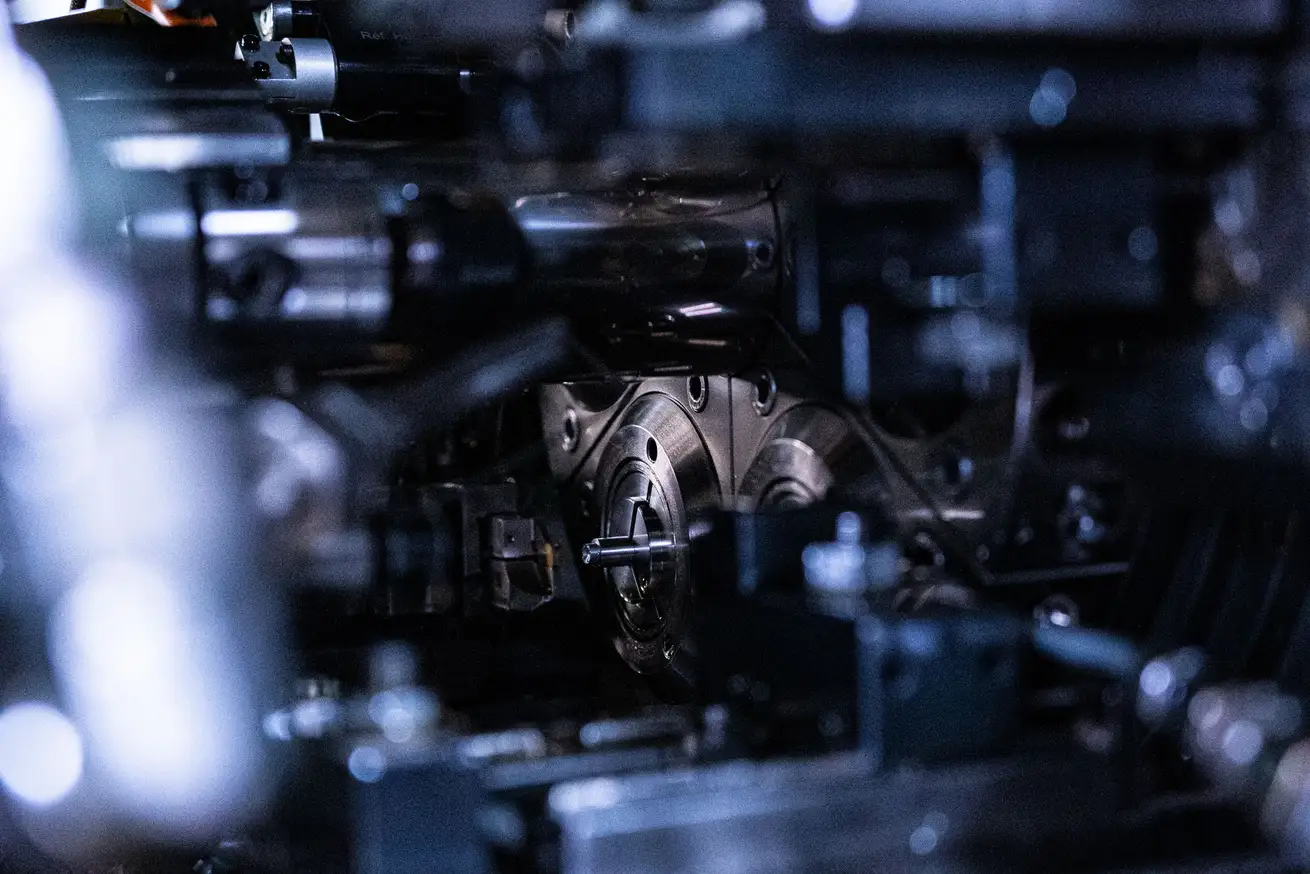

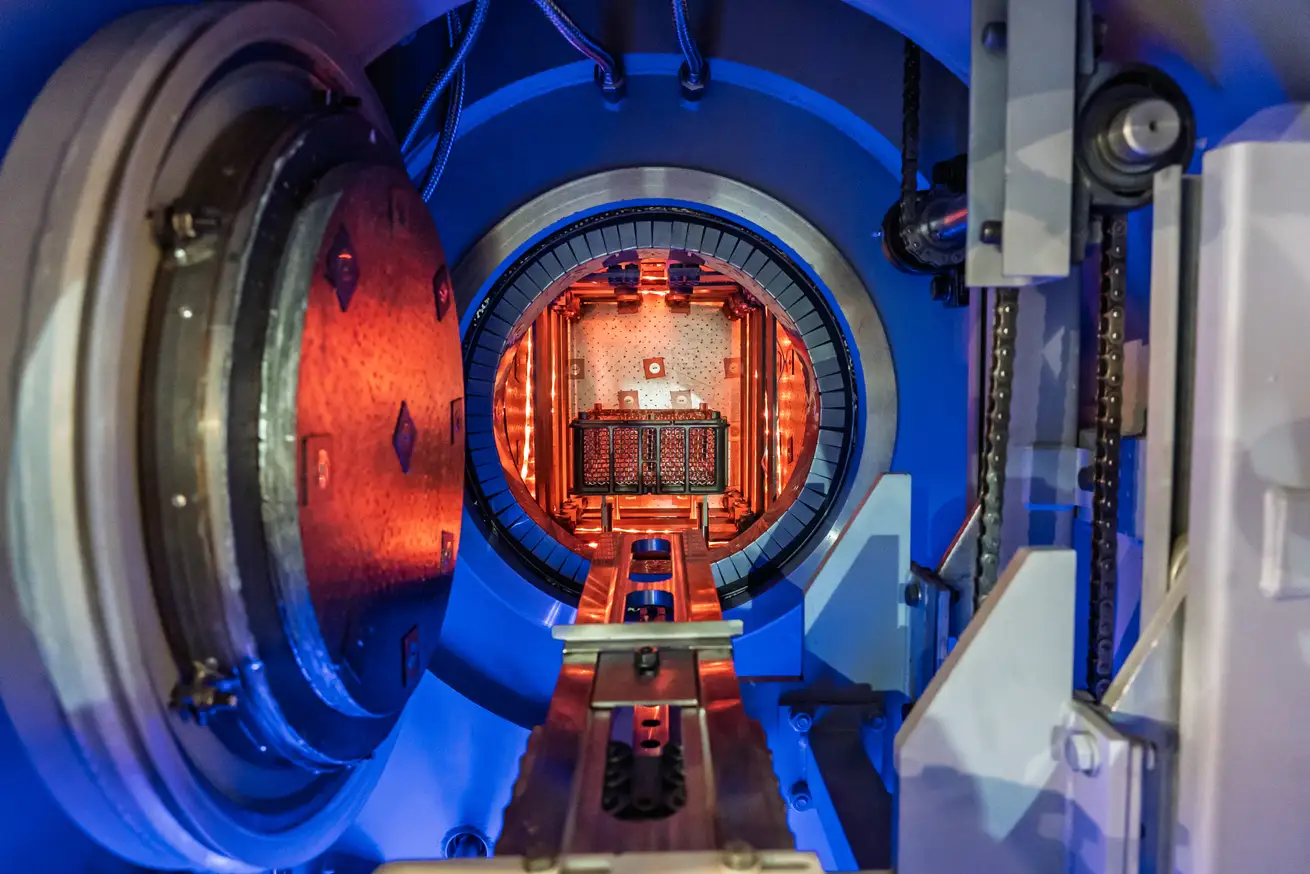

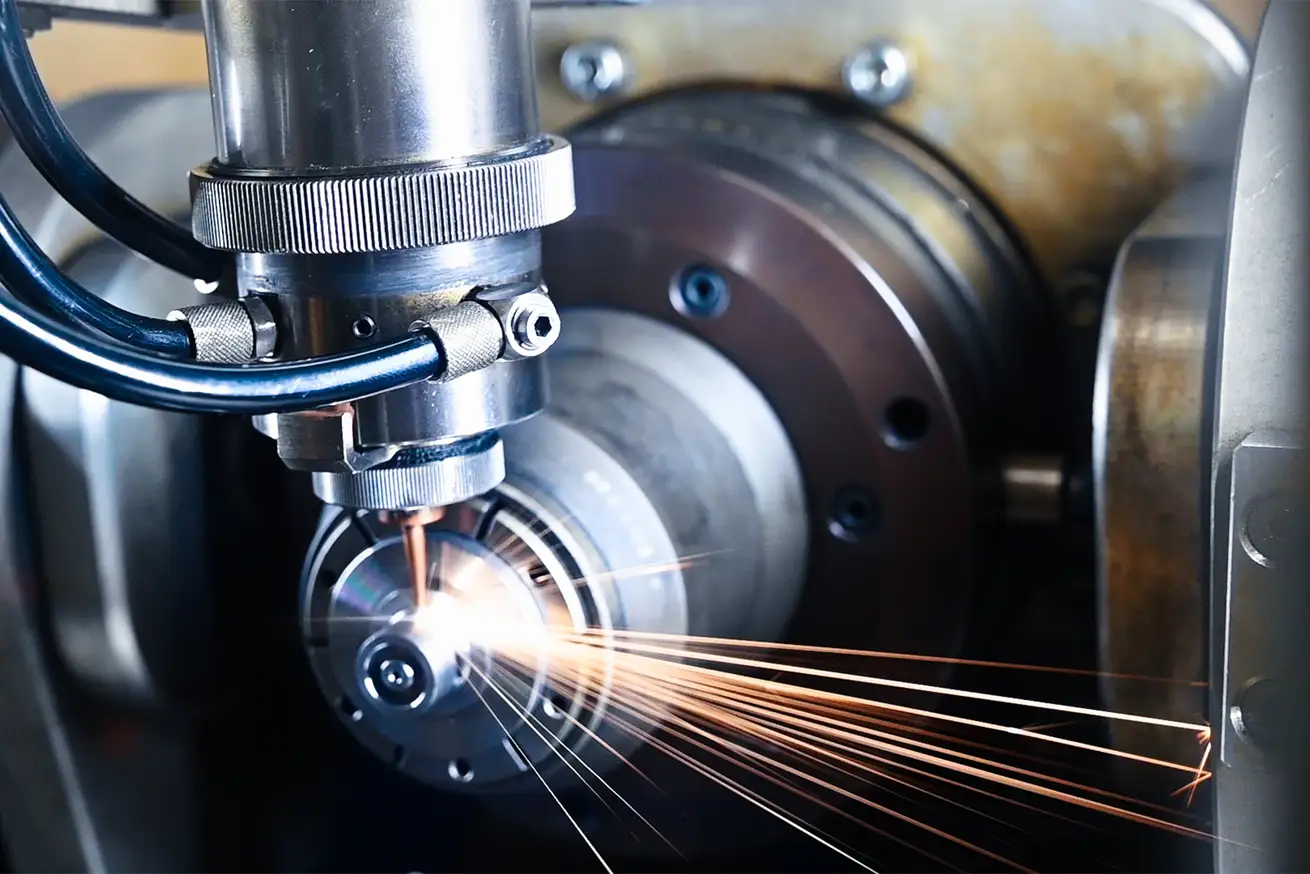

Our Manufacturing Technologies in Detail

Manufacturing technology for demanding turned parts: We develop and optimize tools and production equipment tailored to specific manufacturing requirements. This ensures high productivity, stable processes and top quality at maximum output.

Our customers’ order volumes, requirements and product characteristics are diverse. Thanks to our extensive machinery, we can handle nearly any manufacturing task and process combination quickly, efficiently and reliably.

Quality and Process Reliability

Thanks to our specific expertise, we create competitive advantages and optimization potential for our customers. We design and build custom feeding, assembly and packaging systems tailored to our customers’ requirements.

- Naturally, our quality management is certified (e.g., IATF 16949)

- Traceability and documentation are integral parts of our services

- Testing fixtures are developed and constructed specifically to meet your requirements

- We understand the standards and regulations of the industries we serve

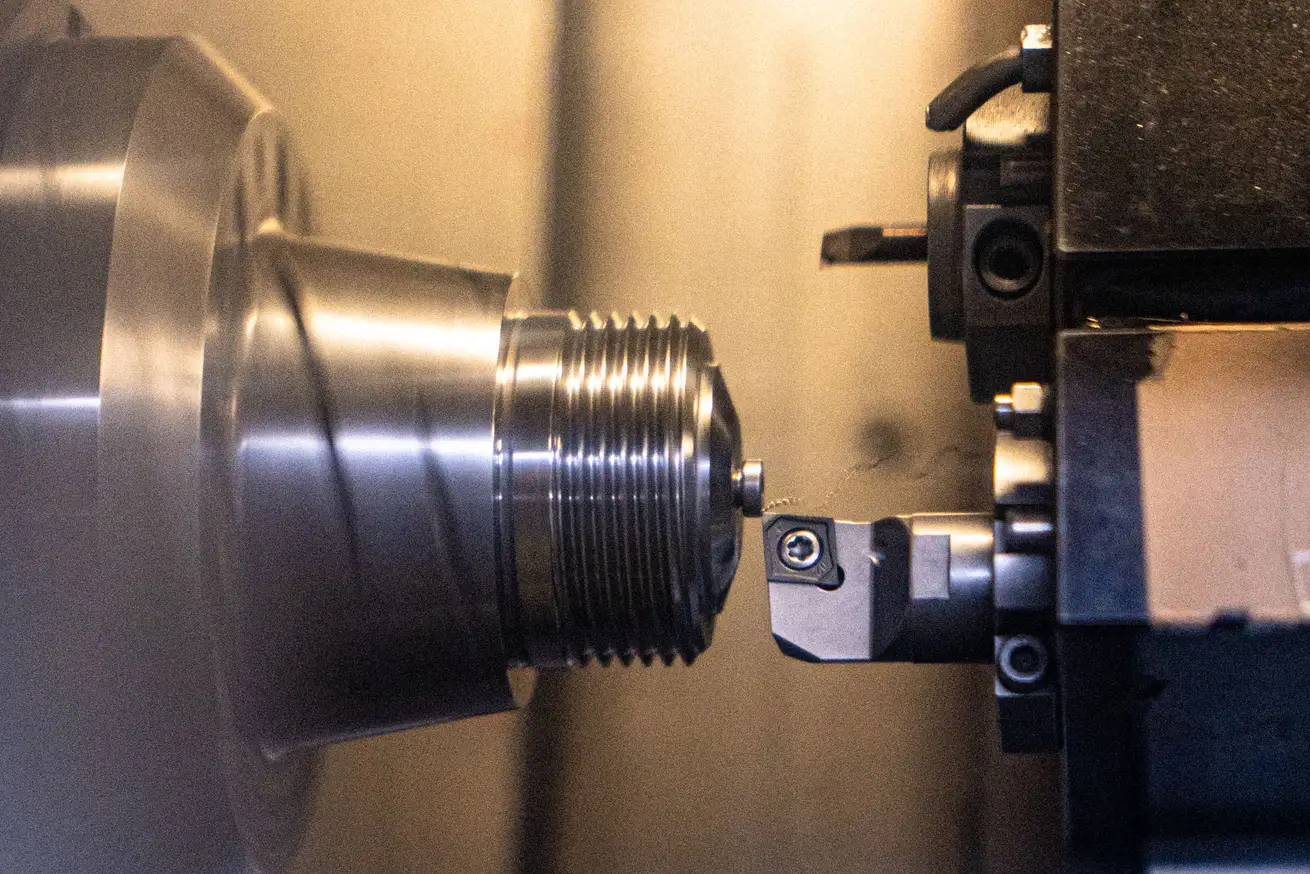

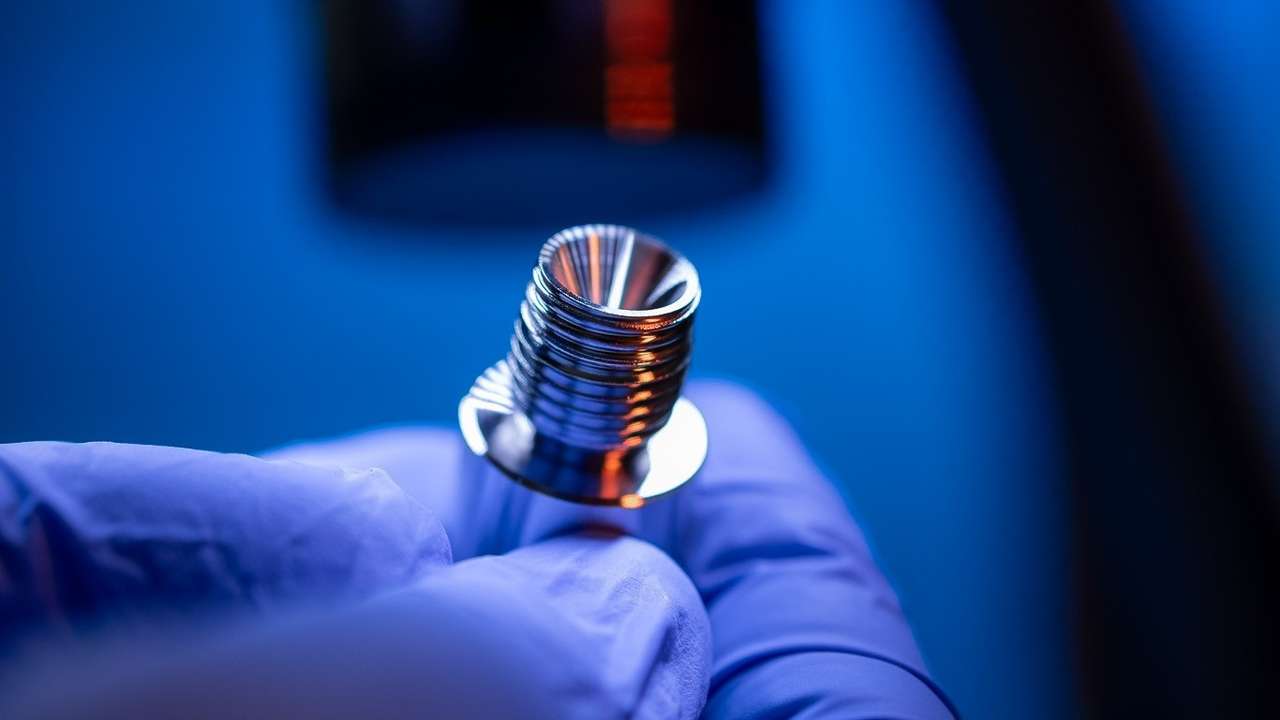

Precision Turned Parts in Series Quality

Many of our technologies come together in turning – the core of our manufacturing. We are specialized in high-precision turned parts made from steel, stainless steel, aluminum and non-ferrous metals – tailored for demanding industries such as automotive, medical technology, and hydraulic systems. We also process special materials such as titanium, PEEK, POM, PAI and others.

How we work together

- 1

Your Inquiry

You share your requirements with us – we record all relevant details and clarify any open questions to ensure a smooth project start.

- 2

Feasibility Check

We assess the feasibility and work with you to optimize your component for efficient and stable series production.

- 3

Individual Offer

You receive a detailed and transparent offer with all relevant information about your project.

- 4

Production & Quality

We manufacture your product according to your specifications – with continuous quality control and complete documentation.

- 5

Delivery & Logistics

We deliver on time according to your instructions – including full handling of customs and logistics processes for safe transport.